Types of Dry Ice

Pellet Dry Ice

Continental Carbonic produces three sizes of dry ice pellets – regular, rice, and blasting pellets:

Cut Dry Ice

Continental Carbonic produces dry ice blocks which we typically cut to standard specifications:

Packaging and Insulated Containers

Dry ice can be packaged bare or in poly bags with a consumer warning label.

Continental Carbonic uses the following insulated dry ice containers to ship dry ice to our commercial customers:

HR 30 and HR 30 SS Insulated Containers

The HR 30 and HR 30 SS containers are the workhorse of our commercial container offerings. These containers hold approximately 1,400 pounds of pellet dry ice and 2,000 pounds of block dry ice. The containers have a capacity of 30 cubic feet, weigh 243 pounds empty with dimensions of 48”(L) x 43”(W) x 42”(H).

HR 11 Insulated Containers

The HR 11 container is a great option for customers with smaller dry ice requirements and for those customers needing an easily moveable container. These containers are available with and without casters and have a hinged lid for better dry ice sublimation control. We recommend shipping blasting pellet in these containers as the lids can be tightly sealed to prevent dry ice clumping and sublimation. These containers hold approximately 500 pounds of blasting pellet dry ice, 600 pounds of regular pellet dry ice and 700 pounds of block dry ice. The container has a capacity of 11 cubic feet, weighs 106 pounds empty and has dimensions of 43″ (L) x 28″ (W) x 35″ (H) (40″ H with casters).

Dry Ice Delivery Options

One of our core philosophies is delivering exactly the dry ice our customers want…when they want it. We deliver dry ice to customers every hour of every day of the year. Continental Carbonic works hard to deliver dry ice to its customers using the least costly, most reliable method. Usually that means that we deliver with our own drivers and trucks but when our existing route structure doesn’t fit with our customers’ needs, we can also utilize common carriers or courier services. Use our Location Finder to find Continental Carbonic near you.

Commercial Uses and Applications

Medical and clinical laboratory shipment companies use dry ice for shipping. Either cut block or pellet dry ice can be used for shipping purposes. Typical cuts are a 10 pound 2″ x 10″ x 10″ cut or a five pound 2″ x 5″ x 10″ cut. These cuts can be delivered without packaging or individually packaged in poly bags.

Dry ice is often delivered to medical shipment customers in HR11 insulated containers that hold approximately 600 pounds of pellet and 700 pounds of cut block. The HR11 has a hinged lid which helps control sublimation and is available on wheels for easy movement throughout a facility. Larger containers are available for larger quantity shipments. When full containers are delivered empty containers from prior deliveries are picked up and returned to our plant.

Product Quality

Continental Carbonic goes to great lengths to minimize the risk of product contamination. We adhere to strict maintenance and sanitization programs for our dry ice production equipment. We require our floor personnel to wear hair nets and anti-bacterial smocks and employ food grade cleanliness practices. Liquid carbon dioxide and dry ice are periodically tested to assure tight product specifications are being met. Digital video cameras monitor the production floor at each of our plants. Insulated containers are thoroughly cleaned and sanitized upon their return to our plants and lids are shrink wrapped once containers are filled. These practices result in Continental Carbonic being able to deliver the highest quality cut block and pellet dry ice in the industry.

On-Time Deliveries

Our medical and clinical product shipping customers require timely delivery of dry ice to allow their distribution centers to meet their outbound shipment schedules on an uninterrupted basis. Continental Carbonic managers stay in close contact with their customer counterparts to insure timely and accurate communication of orders and adjustments.

Do you make the best cupcakes in the county? Or is your farm’s delicious ham in demand from customers living three states away? If so, you may be considering starting or expanding frozen food shipment via online ordering. Continental Carbonic can help connect you with companies who can take away the headache of order fulfillment.

As a small business owner, your main focus is on producing and selling your product. At the end of a long day, the last thing you want to do is head to your local dry ice reseller, attempt to calculate the amount of dry ice needed, and turn your garage into a makeshift shipping center.

By working with a fulfillment company, you can turn fulfillment into a turnkey advantage for your frozen food shipping business, instead of a daily annoyance. Companies that specialize in fulfillment offer the following advantages:

- Save shipping costs – fulfillment companies can offer volume shipping discounts whether you are shipping 10 or 1000 orders a week

- Add credibility to your product with professional packing and shipping

- Stop guessing – fulfillment companies are experts in determining accurate postage, dry ice quantity and container size

- Potentially improve quality by integrating your customer orders with the fulfillment company, allowing for quick and error-free turnaround and daily reporting

- Avoid upfront investment in packaging equipment

- Capture last minute PR or promotional opportunities – a fulfillment company can handle varying volumes without missing a beat

Working with a food fulfillment company is a turnkey process for your frozen food shipping business. Contact us today to discuss which fulfillment company that we do business with can help you increase your business!

The internet fulfillment industry uses cut block dry ice to keep a wide variety of foods frozen during shipping. The most popular food shipments are steaks, ice cream, fund raising cookie dough, pizzas, lobsters, cheese cakes, and cup cakes. Solid block dry ice with production dimensions of 10″ x 10″ x 12″ can be cut into dimensions to match shipping container space and cooling requirements. The dry ice cuts are individually packaged in poly bags that are printed with safe handling warnings.

Dry ice pellets are used extensively in the U.S. meat processing industry to cool meat after slaughter and for shipping. Dry ice pellets are typically delivered in 1,400 pound capacity insulated containers, often in full truckload (approximately 40,000 pounds of dry ice) quantities. Full containers are weighed right before being loaded onto the delivery truck and either off loaded onto the processing plant’s dock or the entire trailer is dropped on the customer’s yard. Empty containers from prior deliveries are loaded back onto the trailer. Upon return to the Continental Carbonic production plant, the empty containers are inspected for damage, repaired if necessary, and thoroughly washed and sanitized.

Our meat processing customers have their choice of either ½ inch or ¼ inch pellets. Continental Carbonic refers to these sizes as regular pellet and rice pellet, respectively.

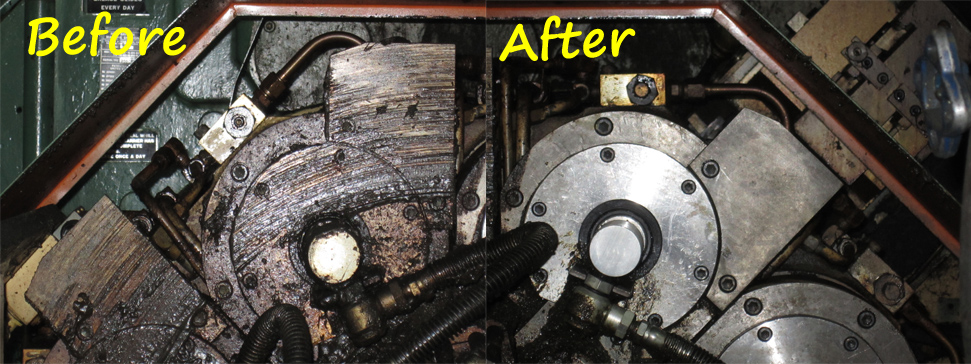

Dry ice blasting is a practical and affordable alternative to traditional cleaning methods such as sand, soda, or water blasting and manual cleaning with solvents.

Dry ice blasting is effective in a wide variety of cleaning applications ranging from heavy jobs like dislodging layers of heavy slag from automotive assembly rails to sensitive applications like removing flux from electronic circuit boards. Dry ice blasting has a wide range of applications in food processing, plastics and molded products, automotive, printing, aerospace, contract cleaning, general maintenance, and many other industries.

Typical cuts for blasting are the 10″x10″x10″ and 5″x5″x10″ blocks as well as high-density pellets.

Pharmaceutical companies use dry ice for shipping and as a cooling agent for research projects. Either cut block or pellet dry ice can be used for shipping purposes and pellet dry ice is typically used for research and development applications. Typical cuts are a 10 pound 2″ x 10″ x 10″ cut or a five pound 2″ x 5″ x 10″ cut. These cuts can be delivered without packaging or individually packaged in poly bags. We frequently deliver to multiple sites throughout a complex. Every site can be set up with a separate account allowing the customer to easily track usage.

Dry ice is often delivered to pharmaceutical customers in HR11 insulated containers that hold approximately 600 pounds of pellet and 700 pounds of cut block. The HR11 has a hinged lid which helps control sublimation and is available on wheels for easy movement throughout a facility. Larger containers are available for larger quantity shipments. When full containers are delivered empty containers from prior deliveries are picked up and returned to our plant.

Product Quality

Continental Carbonic goes to great lengths to minimize the risk of product contamination. We adhere to strict maintenance and sanitization programs for our dry ice production equipment. We require our floor personnel to wear hair nets and anti-bacterial smocks and employ food grade cleanliness practices. Liquid carbon dioxide and dry ice are periodically tested to assure tight product specifications are being met. Digital video cameras monitor the production floor at each of our plants. Insulated containers are thoroughly cleaned and sanitized upon their return to our plants and lids are shrink wrapped once containers are filled. These practices result in Continental Carbonic being able to deliver the highest quality cut block and pellet dry ice in the industry.

On-Time Deliveries

Our pharmaceutical customers require timely delivery of dry ice to allow their distribution centers to meet their outbound shipment schedules on an uninterrupted basis. Continental Carbonic managers stay in close contact with their customer counterparts to insure timely and accurate communication of orders and adjustments.

Institutions of higher learning, medical centers, government research organizations and companies engaged in research and development frequently use dry ice as a cooling agent for research projects. Pellet dry ice is the typical product used for research and development. Frequently customers request that dry ice deliveries be made to multiple locations throughout a research facility or campus. Each delivery point can be set up with a separate account allowing the customer to easily track usage. Our delivery personnel rotate out older dry ice and replenish containers with fresh dry ice. Other customers have deliveries made to a smaller number of dock locations and handle their own distribution.

Cut block dry ice is used in the airline catering industry to keep prepared meals fresh when transported from the airline catering kitchen to the airplane. The standard airline catering cut measures 5″ x 5″ x 7/8″ and weighs ¾ pounds. The cut is packaged in a sealed poly bag for easy handling. The cuts are delivered in an 11 cubic foot insulated container with a hinged lid and on wheels. These containers hold approximately 700 pounds of dry ice cut block. Full containers are delivered to the airline catering kitchen’s dock. Empty containers from prior deliveries are loaded back onto the truck. Upon return to the Continental Carbonic production plant, the empty containers are inspected for damage, repaired if necessary, thoroughly washed and sanitized and stored awaiting the next load.

Topping Off

Continental Carbonic adds a layer of loose dry ice on top of the top row of cut block product to better preserve this layer for use. Without the dry ice “topping”, the top row of cut block will frequently sublimate to an unusable size resulting in significant loss in yield for the catering kitchen.